MS Angles: We provide durable and high strength MS Angles, as per the specifications offered to us, by our customers. Technical specification is according to the Industrial Standards.

| M.S Equal angles thk | Thk (mm) | Wt (kg / m) | | | | | | | | | | |

| size (mm) | 2 | 4 | 5 | 6 | 10 | 11 | 12 | 20 | 22 | 24 | 25 | 20 |

| 35 * 35 | 1.6 | 2.1 | 2.6 | 2.8 | | | | | | | | |

| 40 * 40 | 1.6 | 2.6 | 2.1 | 2.8 | | | | | | | | |

| 45 * 45 | 1.6 | 2.6 | 2.6 | 2.1 | 2.8 | 2.8 | | | | | | |

| 50 * 50 | 1.6 | 2.6 | 2.6 | 2.8 | 2.1 | 2.8 | 2.8 | | | | | |

| 65 * 65 | 1.6 | 2.6 | 2.6 | 2.8 | 2.8 | 2.1 | 2.8 | 2.8 | | 2.8 | | |

| 75 * 75 | 1.6 | 2.6 | 2.6 | | | | 2.1 | 2.8 | 2.8 | 2.8 | | |

| 100 * 100 | 1.6 | 2.6 | 2.6 | | | | 2.8 | 2.1 | 2.8 | 2.8 | | |

| 110 * 110 | 1.6 | 2.6 | 2.6 | | | | | 2.1 | 2.8 | 2.8 | 2.8 | 2.8 |

| 130 * 130 | | 2.6 | | | | | | | 2.8 | 2.8 | 2.8 | 2.8 |

| 150 * 150 | | | | | | | | | 2.8 | 2.8 | 2.8 | 2.8 |

MS Channels: We offer MS Channels in various configuration as desired by our clients. These products are widely reputed for its quality and durability and are available as per Industrial Specifications.

| Designation | Weight per mtr in kg | Depth of section (mm) | Width of flange (mm) | Thickness of flange (mm) |

| Ismc – 75 | 7.14 | 75 | 40 | 7.5 |

| Ismc – 100 | 9.56 | 80 | 8.52 | 6.4 |

| Ismc – 125 | 1.2 | 2.2 | 2.9 | 3 |

| Ismc – 100 | 9.56 | 80 | 8.52 | 6.4 |

| Ismc – 75 | 7.14 | 75 | 40 | 7.5 |

| Ismc – 125 | 1.2 | 2.2 | 2.9 | 3 |

| Ismc – 75 | 7.14 | 75 | 40 | 40 |

| Ismc – 75 | 7.14 | 75 | 40 | 40 |

| Ismc – 125 | 1.2 | 2.2 | 2.9 | 3 |

| Ismc – 75 | 7.14 | 75 | 40 | 7.5 |

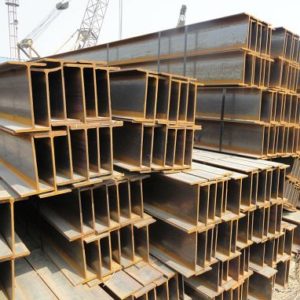

MS Beam: MS Beam are useful for industrial usage, widely the building and construction industry. These beams in mild steels are also known for their ability to withstand extreme weather conditions. These are available in technical specifications as detailed to us by our customers.

| Size | Weight in kgs. Per Feet | Weight in kgs. Per Mtr |

| ISMB 100 * 50 | 2.432 | 7.979 |

| ISMB 125 * 70 | 4.085 | 13.4 |

| ISMB 150 * 75 | 4.573 | 15.0 |

| ISMB 175 * 85 | 5.975 | 19.6 |

| ISMB 200 * 100 | 7.743 | 25.4 |

| ISMB 250 *125 | 11.371 | 37.3 |

| ISMB 300 * 140 | 14.054 | 46.1 |

| ISMB 350 * 140 | 15.975 | 52.4 |

| ISMB 400 * 140 | 18.780 | 61.6 |

| ISMB 450 * 150 | 22.073 | 72.4 |

| ISMB 500 * 180 | 26.493 | 86.9 |

| ISMB 600 * 210 | 37.500 | 123.0 |

Ms Flats, Squares, Rounds and CTD / TMT bars: We provide high quality Ms Flats, Squares, Rounds and Rebars (TMT) that are highly acknowledged in the market for durability and reliability.

| Grades | Yield (min. Mpa) | UTS (min. Mpa) | Elongation (min%) |

| FE - 415 | 500 | 545 | 12.5 |

| FE - 500 | 500 | 545 | 12.5 |

| FE - 550 | 550 | 585 | 8.5 |

| Grades | Specific Weight g. mtr | Min | BIS Standard Tolerance Grams / Meter Max. |

| 8 | 386 | 358 | 425 |

10

| 671 | 844 | 320 |

| 12 | 671 | 574 | 660 |

| 16 | 1580 | 1500 | 1659 |

| 20 | 2580 | 2500 | 2659 |

| 25 | 3580 | 3500 | 3659 |

| 28 | 4580 | 4500 | 4659 |

| 32 | 6580 | 6500 | 6659 |